The safe operation of machines and systems is key for employee protection. Fast Automation’s approach to safety is comprehensive and methodical. To ensure both the safe operation of your machines and systems and to meet Australian Standards, Fast Automation boasts TUV certified engineers with decades of engineering experience who can conduct machinery and plant automation functional safety assessments, audits and design reviews for existing or new equipment.

Fast Automation offers a complete range of services to ensure the safety of personnel and equipment. We can provide comprehensive reports, design assistance and services in the following safety related areas.

Fast Automation works to comply with the following Australian Standards:

Hazardous Areas

In addition to this Fast Automation has engineers qualified for design in Hazardous areas with IECEx Certifications. We are certified to work with Group l, II, and III Flammable and Combustible Materials.

Fast Automation follows these Australian Standards when working in Hazardous areas:

The goal of these strict standards and the engineers at Fast Automation are to eliminate occupational health hazards at the source and to ensure the safety and wellbeing of people at work. Whilst also involving workers and their representatives in all occupational health and safety issues.

These standards allow Fast automation to provide improvements in project productivity, efficiency and the moral of employees and customers.

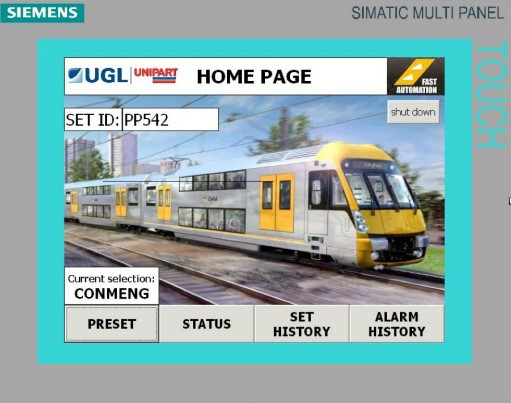

UGL Unipart Jacking Road

UGL Unipart nominated Fast Automation to be their preferred automation provider and as such awarded a large automation project for the automated maintenance of trains. The system utilises a Siemens S7-300 safety CPU and WinCC flexible touch panel. One difficulty with the automated movement of such large items is safety. The project required a Main Control Panel and 8 large remote panels each with 140 Safety IO on them. Another interesting feature of this system was the radio control pendants with safety